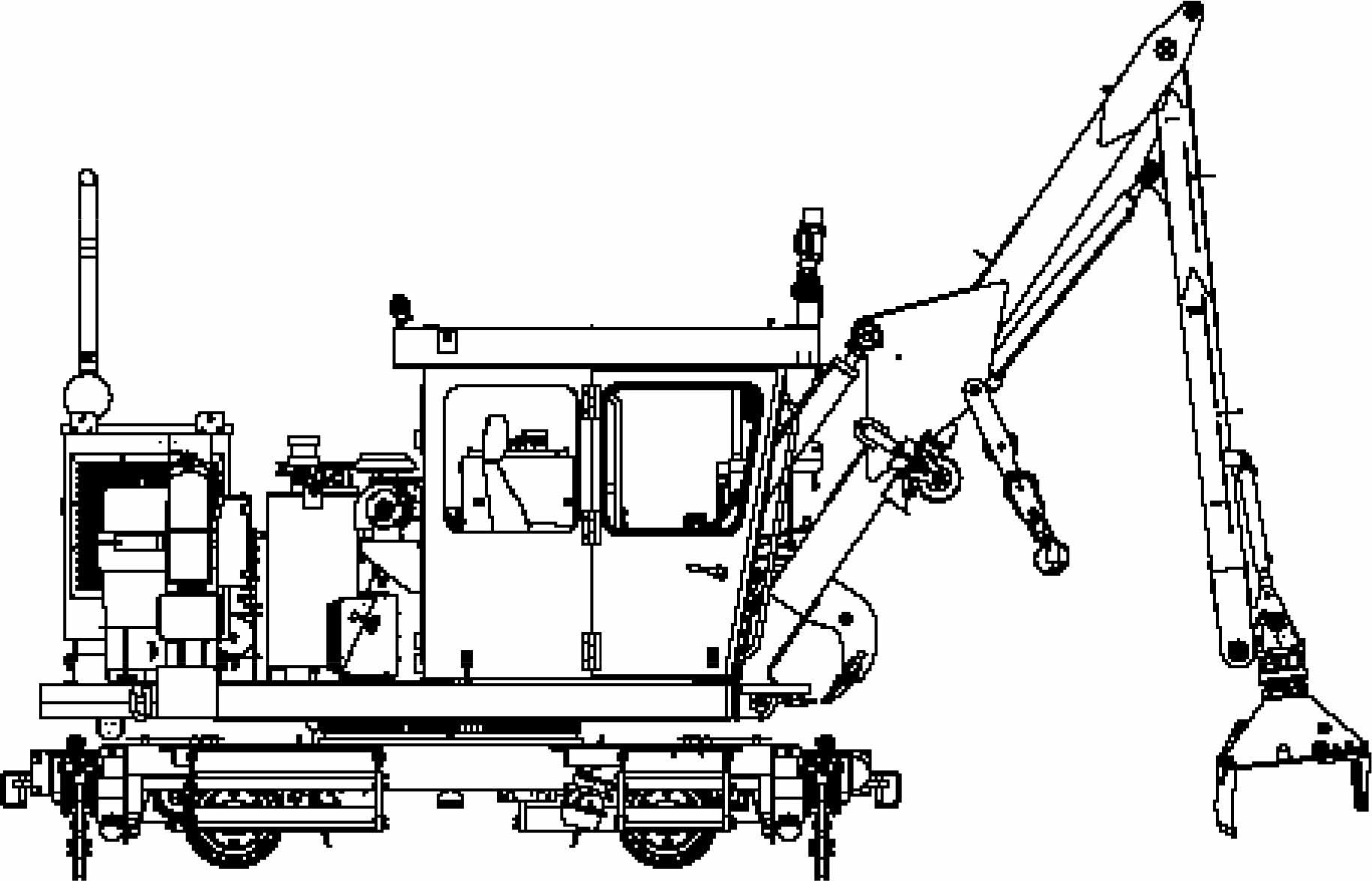

凯杰夫® 12-12 Bridge Crane

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

我们的Kershaw®型号12-12桥式起重机旨在执行桥梁和开放式甲板上衣,型号12-12桥式起重机最大提升能力为1200磅。(544千克)在25英尺处。从轨道的中心。上层甲板和领带抓斗能够连续旋转360°。桥式起重机能够处理桥梁领带,帽子,桁条等桥梁组件。

TECHNICAL DETAILS

Frame:Welded construction, lower frame is structural steel and 1” (25.4 mm) thick steel plate for the slewing ring support. Upper deck is structural steel and formed deck plates. Frame covered by Five (5) Year Warranty. Oversize 46 7/8 inch diameter slewing ring rated for 80,000 ft-lb. Remote grease fittings for slewing ring and axle bearings. 8 channel 6,000 psi hydraulic swivel is accessible from the upper deck.

Engine:Caterpillar C4.4, 131 HP @ 2200 rpm Tier IV Final

Transmission and Axles:3英寸(76毫米)直径实心轴chain drive from separate hydraulic motors driving both axles. Travel speed: 20 mph (32 km/hr). Two (2) propel drive motors for quicker response in work mode. #100 drive chain with hardened tooth sprockets.

液压系统:Hydrostatic propel system pressure compensated piston-type pump direct coupled to engine. Deck rotation by hydraulic motor through gearbox. Hydraulic oil is filtered through a 100 mesh (145 micron) suction screen and 10-micron return line filter. Manifold-type stack valves for improved serviceability. Remote oil cooler accessible from ground level with dual electric cooling fans. Electric emergency pump.

Electrical System:24VDC负面,100AMP交流发电机,颜色编码和编号接线。

Air System:Air compressor, engine oil-lubricated, air-cooled; pressure - 100-120 psi (689-927 kPa), 15-gallon air tank.

Cab:Large enclosed cab with 99.5 cubic foot capacity. Ergonomically designed seat. Large front windshield with an unobstructed view of boom operation through full range of motion. Hydraulic pilot-pressure bottom-ported joystick controls on operator seat with heat shields. Self-contained hydraulically driven air conditioner/heater/pressurizer unit mounted on rear wall of cab (roof mount optional). Remote-controlled boom travel lock. Rubber suspension ladder steps. No service items located on cab roof on standard machine.

Wheels and Brakes:16” (406 mm) cast steel wheels. External, individual composite brake shoes applied directly on the vertical centerline of wheel tread. Service brakes are air applied, spring released. Emergency/parking brakes are spring applied, air released. Optional hydraulic brakes available.

Capacities:Fuel: 75 gal. (284 liters), Hydraulic: 70 gal. (265 liters).

Weight:23,000 lbs

Boom:超宽32英寸(813毫米)扩散底根臂安装。GV-12抓斗旋转器。配备4,000磅的容量绞车。

Optional Equipment:Basket grapple; single tie grapple; two tie grapple; timber grapple; concrete tie grapple; timber crane package; boom-mounted flail mower.

KERSHAW® MOW OVERVIEW

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

销售康泰克TS

割草副总裁

RAIL EQUIPMENT SALES

VEGETATION EQUIPMENT SALES

OEM零件,服务和保修

国际销售

Randy Chubaty

National Sales Manager - Rail

Fairmont, MN

507-384-2577

Jennifer Kincaid

Sales Executive - Rail

Bradenton, FL

414-369-9290

Corey Helper

National Sales Manager

Montgomery, AL

251-610-6347

Jason Sasser

Sales Executive - Vegetation/Utility

Birmingham, AL

205-492-8006

Sid Harmon

Technical Sales Executive - Vegetation/Utility

Montgomery, AL

334-782-9906

Parts Hotline

1-888-660-5252

服务热线

1-833-537-7782

Kirk Schirra

Aftermarket Manager - Sales, Service & Warranty Support

Montgomery, AL

Office:334-387-9301

Cell:814-431-2129

Julian Howard

Sales Manager, Aftermarket Parts

Office:334-387-9426

Fax: 334-387-9400

Cell:334-235-0922

Russell Forks

Service Manager

Montgomery, AL

334-799-4061

Chuck Ewing

Vice President - International Trackwork

+1-219-680-9096

David May

International Sales Director

+1-469-934-8284

Adam Todd

国际业务发展总监

+44 (0) 7966 337924

luiz melo.

Business Development Manager Latin America

Phone: +55(11)4070-5288

Cell:+55 (11) 97019-0338

Rob de Beer

澳大利亚业务发展经理

+61 (0) 408 010 983

RELATED MACHINES

-

凯杰夫® 12-12 Bridge Crane

Learn More -

Kershaw®12-12领带起重机

Learn More -

Kershaw®32-10刷切割机

Learn More -

Kershaw®34-7水平废料

Learn More -

凯杰夫® 35-13 Tie Plate Sweeper

Learn More -

Kershaw®35-14双扫帚

Learn More -

凯杰夫® 38-7 Kribber Adzer

Learn More -

凯杰夫® 44-2 Rotary Scarifier

Learn More -

凯杰夫® 4600 Ballast Regulator

Learn More -

凯杰夫® 47-6 Tie Replacer

Learn More -

凯杰夫® Ballast Regulator Model 66

Learn More -

凯杰夫® KSC2000 Shoulder Cleaner

Learn More -

凯杰夫® Model 60 Sand Remover

Learn More -

凯杰夫® Model 60 Snow Remover

Learn More -

凯杰夫® RH446 Rail Heater

Learn More -

Kershaw®蝎子RS70 DL斜坡

Learn More -

凯杰夫® SkyTrim 75HRT

Learn More