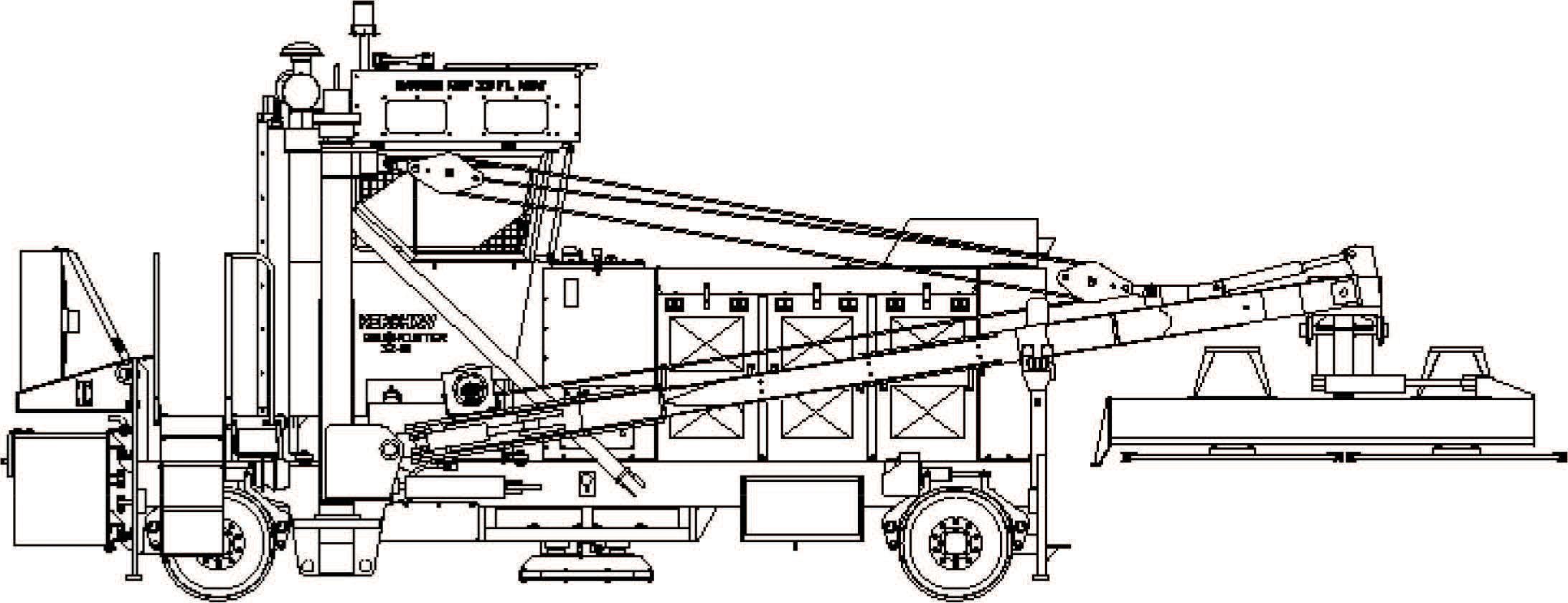

Kershaw®32-10刷切割机

Progress Rail’s Maintenance-of-Way (MOW) division was born out of the movement toward mechanization in the railroad industry and introduced the first Kershaw® Ballast Regulator in 1945. Today, Progress Rail supplies Kershaw® MOW equipment, providing machines to all Class I railroads, transit and short lines and contractors around the world.

KERSHAW®型号32-10 Brushcutter从铁路右路清除刷子和悬垂分支。它能够从轨道中心切割高达30英尺(9144毫米),并在可生物降解的覆盖物后面留下。

TECHNICAL DETAILS

Frame:Welded construction of side frame member and formed plate cross-members.

重量:62,000磅(28123.2千克)

Engine:Caterpillar C9.3B 335 hp @ 2200 rpm Tier IV Final

Propel系统:Closed-loop variable displacement axial piston pump driving a fixed displacement axial piston motor. Maximum travel speed is 35 mph with full-time four-wheel drive.

Transmission and Axle:静液压传输驱动到Go Gearbox上的4速偏移。具有自动锁定差速器的前后汽车型轴通过带有滑动接头的心脏轴驱动。

Wheel and Brakes:28 inch cast steel wheels are bolted to axle hubs. 4-wheel clasp brakes are axle mounted. Service brakes are air applied and spring released. Parking brakes are spring applied and air released. Suspension system utilizes coil springs.

空气系统:Air compressor, engine oil-lubricated, air-cooled; 13 cu. ft free air volume @ 2200 rpm; system pressure 100 psi; 613 cu. in. air tank. Air is supplied to service brakes through a pressure reducing valve with pressure gauge. Parking brake is set by means of an electrically activated air dump valve. System is also equipped with dual-tone air horns and a safety relief valve.

液压系统:发动机通过离合器驱动三重泵驱动器。两个三重泵为刀具电机和刀头控制电路供电。

Electrical System:24 volts dc negative ground; 150 amp alternator; color coded and numbered wiring.

Cab:驾驶室可容纳两个操作员(每个刀头一个)。提供足够的高度,用于站在入口门和后部。每个操作员都有一组用于控制方向的脚踏板。驾驶室配有加热器,空调和加压单元。驾驶室侧壁是双层墙体结构(1/4“A514超过11Ga。),带Lexan®Marguard窗户。

容量:油箱:110 gallons.Hydraulic tank:100 gallons.

Cutterhead:Booms can rotate a 10 ft. wide double disk cutterhead outboard up to 30 ft. from rail centerline and 45° up/40° down from horizontal. Single boom operation is made possible by shifting a counterweight hydraulically to opposite side of the live cutterhead.

转盘系统:The Brushcutter has a turntable and can be turned manually.

Controls:Two 5-section valves (one for each operator) control the functions of the respective cutterheads. Boom in/out, up/down. and cutterhead pitch, tilt, and rotate are controlled by these valves. Travel direction is controlled by hydraulic foot pedals at each operator position.

Kershaw®Mow概述

PARTS HOTLINE: 1-888-660-5252

SERVICE HOTLINE: 1-833-537-7782

销售联系人

MOW VICE PRESIDENT

RAIL EQUIPMENT SALES

植被设备销售

OEM PARTS, SERVICE & WARRANTY

国际销售

Corey Helper

National Sales Manager

蒙哥马利,al.

251-610-6347

杰森萨瑟

Sales Executive - Vegetation/Utility

Birmingham, AL

205-492-8006

哈米德

Technical Sales Executive - Vegetation/Utility

蒙哥马利,al.

334-782-9906

零件热线

1-888-660-5252

Service Hotline

1-833-537-7782

Kirk Schirra

售后经理 - 销售,服务和保修支持

蒙哥马利,al.

办公室:334-387-9301

Cell:814-431-2129

Julian Howard

Sales Manager, Aftermarket Parts

办公室:334-387-9426

Fax: 334-387-9400

Cell:334-235-0922

罗素叉子

服务经理

蒙哥马利,al.

334-799-4061

Chuck Ewing

副总裁 - 国际田径工作

+1-219-680-9096

大卫五月

国际销售总监

+ 1-469-934-8284

亚当托德

Director, International Business Development

+44 (0) 7966 337924

Luiz Melo

商业发展经理拉丁美洲

电话:+55 (11) 4070-5288

Cell:+55(11)97019-0338

Rob de Beer.

Business Development Manager Australia

+61(0)408 010 983

相关机器

-

Kershaw®12-12桥式起重机

学到更多 -

Kershaw® 12-12 Tie Crane

学到更多 -

Kershaw®32-10刷切割机

学到更多 -

Kershaw® 34-7 Horizontal Scarifier

学到更多 -

Kershaw® 35-13 Tie Plate Sweeper

学到更多 -

Kershaw® 35-14 Double Broom

学到更多 -

Kershaw® 38-7 Kribber Adzer

学到更多 -

Kershaw® 44-2 Rotary Scarifier

学到更多 -

Kershaw® 4600 Ballast Regulator

学到更多 -

Kershaw®47-6领带替代品

学到更多 -

Kershaw® Ballast Regulator Model 66

学到更多 -

Kershaw®KSC2000肩部清洁器

学到更多 -

Kershaw®型号60砂卸镜

学到更多 -

Kershaw® Model 60 Snow Remover

学到更多 -

Kershaw®RH446轨道加热器

学到更多 -

Kershaw® Scorpion RS70 DL Ramp

学到更多 -

Kershaw®Skytrim75hrt.

学到更多